Our science

At DIRTEA, we don’t just sell mushrooms, we deliver the purest, most potent, and most effective functional mushroom extracts available.

It takes science to be DIRTEA: Pure, Potent and Proven.

Being DIRTEA means the best mushrooms backed by the best science. From selecting the finest organic fungi to perfecting our double-extraction process, every step is rooted in precision and care. Our 3000mg servings of pure mushrooms are sourced from optimal climates, third-party tested, and meticulously extracted to ensure maximum potency and absorption. With every DIRTEA, you're experiencing nature's most powerful ingredients, delivered just as they should be—pure and potent from forest to you.

What makes DIRTEA

the best?

Each serving packs 1,000-3000mg of high-extract, 100% fruiting body mushrooms, ensuring maximum bioavailability and real results.

With functional mushrooms on the rise, quality matters more than ever. Many products on the market use mycelium on grain (mostly starch) or un-extracted powders that lack potency.

At DIRTEA, we’re committed to the highest extraction standards, purity, and third-party testing.

So, as you pour yourself a cup of your favourite DIRTEA mushroom blend or Gummy, know that you’re fuelling your mind and body with nature’s most powerful adaptogen.

Let’s dive in - because when it comes to mushrooms, potency, purity, and trust are everything.

Recommended by Dr. Tara Swart

"DIRTEA stand for health, education and community. I have used adaptogenic mushrooms for many years and this is the brand I love on so many levels.”

Renowned neuroscientist, medical doctor & our Chief Science Officer.

What goes into our products?

For our core mushroom range, just mushrooms. That’s it. 100% pure, fungi-powered goodness.

DIRTEA Dictionary

Our mushroom farms

The story of our process begins in the rolling mountains where our forest-shaded greenhouses and small family farms are located, far away from the urban lowland centres.

All our mushrooms are organically grown. However, the exact location will vary depending on the climate best suited for the strain. For example, the Reishi and Lion’s Mane are grown in shade houses in more humid areas, Cordyceps are grown indoors with precise climate controls, and Chaga is wild harvested.

Once grown, it’s time for picking.

Fruiting body vs. mycelium

Before we jump ahead, it’s worth giving you a quick mycology lesson to better appreciate the care that goes into every batch.

A mushroom is the reproductive part of the organism we call fungi.

Fungi have two main parts: the mycelium (which can be compared to the tree) and the mushroom (which can be compared to the fruit). The mycelium lives underground and can spread for hundreds of miles. When the mycelium wants to reproduce, one of the ways is to produce a fruit - a mushroom. The mushroom releases spores, which mate to form more mycelium.

Our extracts are made from only pure mushrooms and DO NOT contain any mycelium or the grains and wood on which the mycelium is grown on.

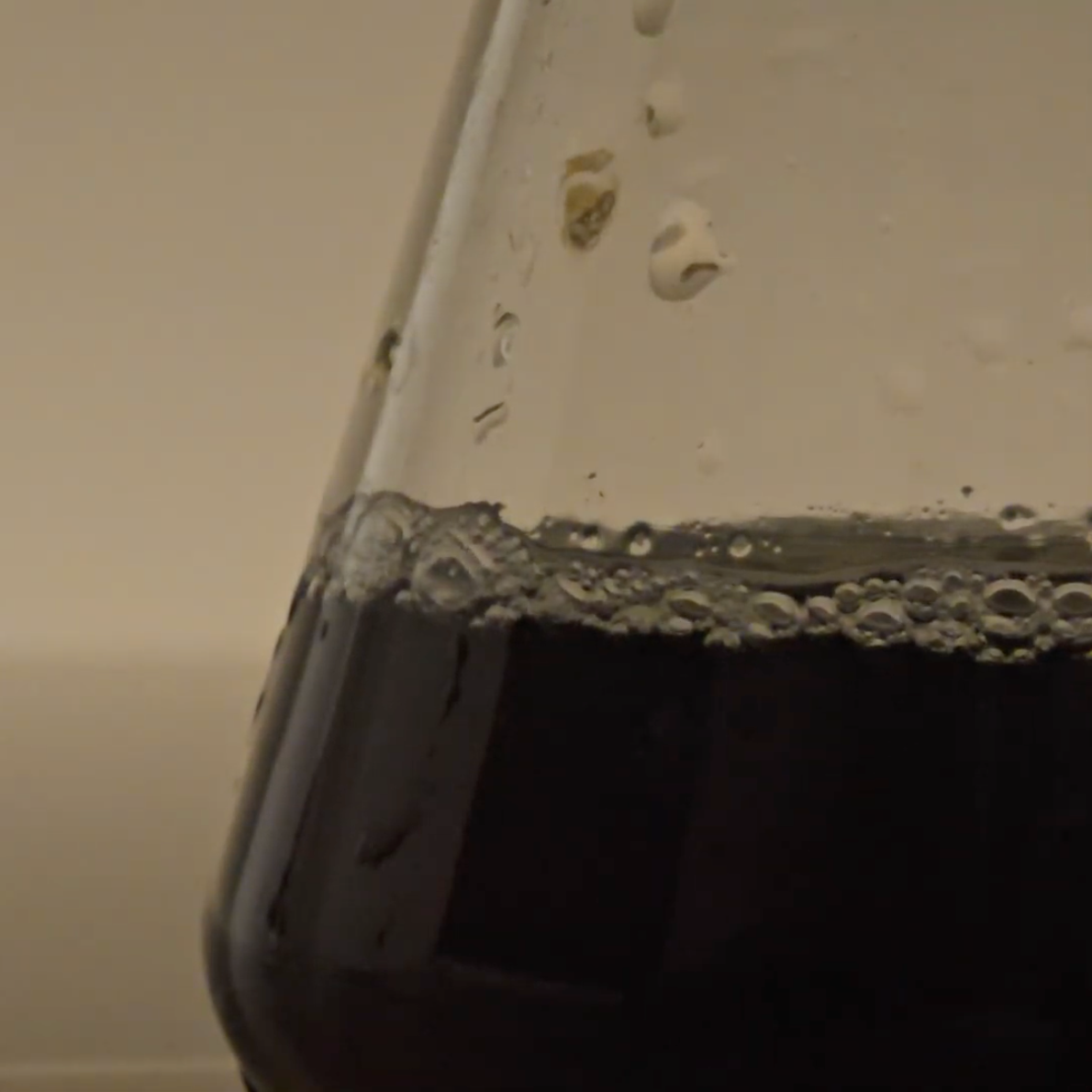

Extraction process

This is the fun part - as every single one of our mushrooms is either hand selected by a team of pickers or forged by farmers. Next, they’re dried and crushed into a fine powder to create more surface area - allowing us to access more of the mushroom during the first extraction.

Depending on the strain, we use large pressure cookers filled with pure filtered water, which heats the cells and cracks the cell wall. We repeat this process up to three times to ensure all the target compounds are separated from the chitin. On its own, chitin is indigestible, but inside, it holds the secret: polysaccharides and beta-glucans. Once the cell wall is broken, these are released and become bio-available, so our body can metabolise them, and we can benefit from their fungal compounds.

Spray‑drying

Once the pressure cooking is completed, we separate the liquid from the fibre, then concentrate it to reach a specific density. Now, it’s ready for spray drying - which dries up any remaining moisture between the granules to prevent mould.

Next, we run the fine powder through a finer sieve to catch any coarse particles.

Testing

Then the only step left is to test our powder extracts for heavy metals, moulds and other unwanted chemicals. When the powders pass the quality control testing, we send them to the final testing phase to determine the polysaccharide content - by shining UV light through the powder to count the percentage of polysaccharides.

Final stage

We then package the extracted and tested concentrate powders so they look beautiful and are ready to serve.

Our extracts are made from only pure mushrooms and don't contain any mycelium or the grains and wood on which the mycelium is grown on.